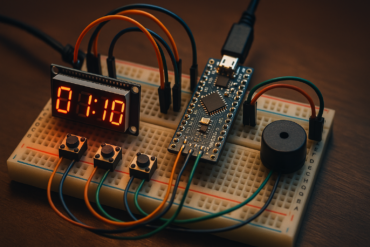

I have a small hatchback car with manual transmission and I often think to display current gear in the dashboard instrument panel, So I decided to make something fancy, In this tutorial we are going to build a car gear position indicator for a manual transmission (H-pattern) with 5 forward gears + 1 reverse using:

- Arduino Nano

- 6 Limit Switches (for gear detection)

- 0.96″ I2C OLED Display (typically SSD1306, 128×64)

⚙️ System Overview

Each gear position has a dedicated limit switch:

- Gear 1 → Switch 1

- Gear 2 → Switch 2

- …

- Gear R (reverse) → Switch 6

You’ll read these switches as digital inputs and display the active gear on the OLED.

🧰 Components Needed

- Arduino Nano

- SSD1306 OLED (I2C)

- 6x Limit Switches

- Pull-down resistors (or use internal pull-ups and wire switches to ground)

- Jumper wires, breadboard or PCB

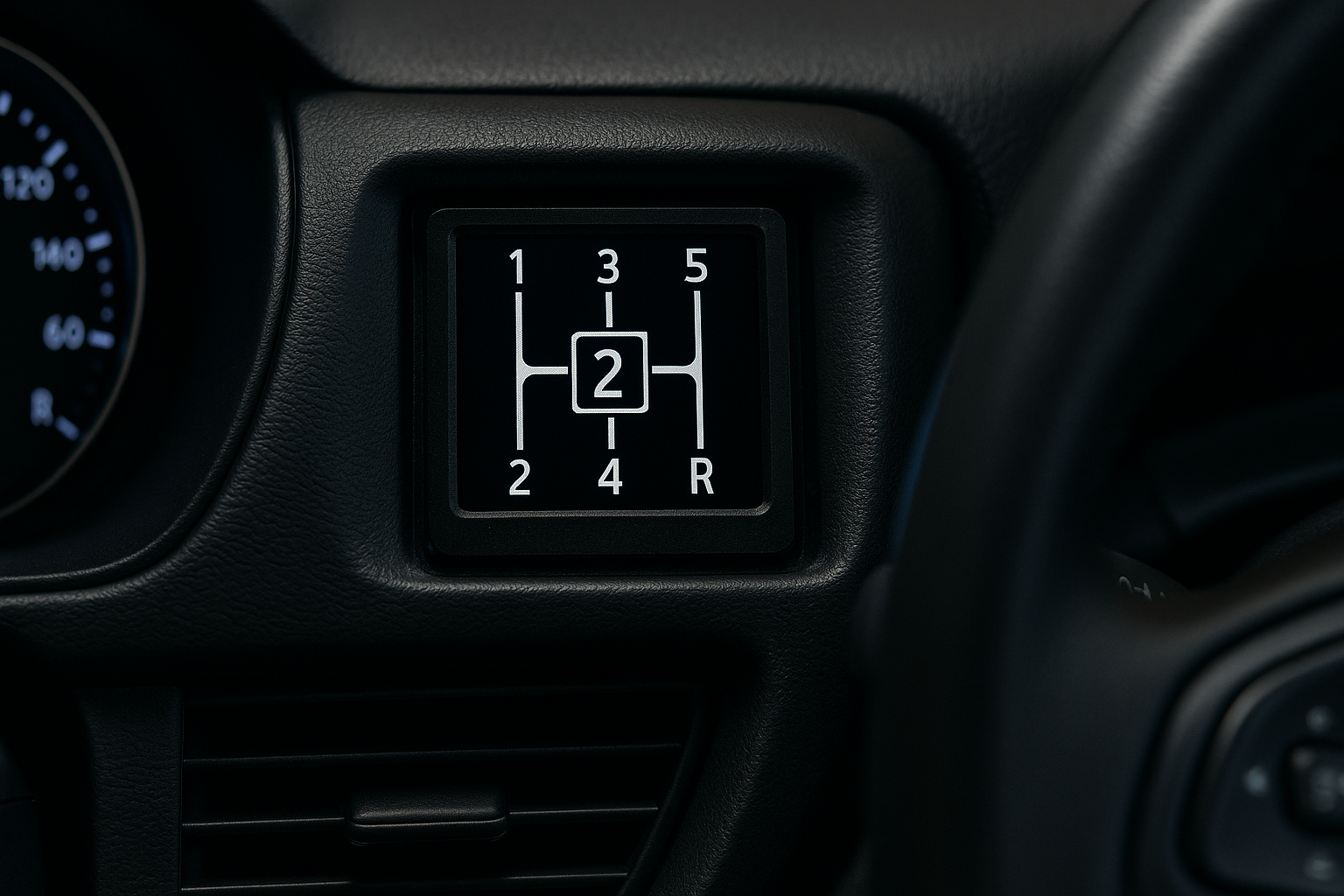

⚙️ Concept: H-Pattern Manual Transmission Gear Indicator

Goal: Display a visually clear and attractive H-pattern gear layout with real-time gear selection based on limit switch input.

🧩 Components Breakdown

| Component | Purpose |

|---|---|

| Arduino Nano | Reads gear position from limit switches |

| 6 Limit Switches | One per gear (1–5 + R), mounted to shifter |

| OLED Display | Shows the H-pattern layout with gear labels |

| Graphics (OLED or Simulation) | Visual representation of gear state |

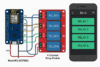

🖥️ OLED Wiring (I2C)

| OLED Pin | Arduino Nano Pin |

|---|---|

| VCC | 5V |

| GND | GND |

| SDA | A4 |

| SCL | A5 |

🔌 Limit Switch Wiring Example

Wire one side of each limit switch to GND, the other side to a digital pin (D2–D7 for example). Enable internal pull-up resistors in code.

🛠️ Notes

- When no gear is engaged, all switches are unpressed → system shows “N” (Neutral).

- You can improve it by debouncing the switch inputs if needed.

- Mount the switches such that only one is pressed at a time.

- If 2 or more are pressed (like during shift), you can prioritize or show “Shifting”.

🔲 OLED Gear Layout Example (H Pattern)

1 3 5

| | |

2 4 RWe’ll draw all gears statically, and dynamically highlight the active gear by inverting its number (or drawing a box around it).

🧾 Arduino Code – H Pattern Gear Display with Highlight

Ensure you have these libraries installed:

#include <Wire.h>

#include <Adafruit_GFX.h>

#include <Adafruit_SSD1306.h>🔧 Customization Tips

- You can adjust

gearXandgearYvalues to better fit your screen or layout. - Add connecting lines between gears if desired (like drawing vertical/horizontal lines for realism).

- Add an optional

"N"(Neutral) box if no gear is pressed.

✅ Features

- Full H-pattern layout

- Gear connections (lines)

- Highlighted active gear

- Optional Neutral display if no gear is selected

- Smooth and clean layout

🖥️ How It Works

1. Gear Detection via Limit Switches

Each gear position in your physical gear shifter presses a unique limit switch when selected.

- Limit switches are connected to digital pins on the Arduino Nano.

- Each switch is pulled HIGH via

INPUT_PULLUP. - When a gear is engaged, its switch goes LOW → Arduino detects it.

2. Gear Mapping Logic

In the Arduino sketch:

- We scan all switch inputs.

- The first detected LOW input tells us which gear is active.

- If no gear is active, we consider it Neutral.

3. OLED Display Update

Based on the active gear:

- A pre-drawn H-pattern is shown with all gear positions.

- The current gear is highlighted (by color inversion or glow effect).

- If no gear is pressed, a Neutral “N” is displayed.

🧾 Arduino Code upload by using Arduino IDE

#include <Wire.h>

#include <Adafruit_GFX.h>

#include <Adafruit_SSD1306.h>

#define SCREEN_WIDTH 128

#define SCREEN_HEIGHT 64

Adafruit_SSD1306 display(SCREEN_WIDTH, SCREEN_HEIGHT, &Wire, -1);

// Gear switch pins: 1 to 5 and Reverse

const int gearPins[6] = {2, 3, 4, 5, 6, 7};

const char* gearLabels[6] = {"1", "2", "3", "4", "5", "R"};

// Gear screen positions

const int gearX[6] = {10, 10, 50, 50, 90, 90}; // x-coords

const int gearY[6] = {0, 30, 0, 30, 0, 30}; // y-coords

int activeGear = -1;

void setup() {

for (int i = 0; i < 6; i++) {

pinMode(gearPins[i], INPUT_PULLUP);

}

if (!display.begin(SSD1306_SWITCHCAPVCC, 0x3C)) {

while (true); // halt if OLED not found

}

display.clearDisplay();

display.display();

}

void loop() {

activeGear = -1;

for (int i = 0; i < 6; i++) {

if (digitalRead(gearPins[i]) == LOW) {

activeGear = i;

break;

}

}

drawHPattern(activeGear);

delay(100);

}

void drawHPattern(int highlight) {

display.clearDisplay();

// Draw vertical lines (gear gates)

display.drawLine(18, 10, 18, 54, SSD1306_WHITE); // 1-2

display.drawLine(58, 10, 58, 54, SSD1306_WHITE); // 3-4

display.drawLine(98, 10, 98, 54, SSD1306_WHITE); // 5-R

// Draw horizontal connectors

display.drawLine(18, 20, 98, 20, SSD1306_WHITE); // upper line

display.drawLine(18, 44, 98, 44, SSD1306_WHITE); // lower line

// Draw gear numbers

for (int i = 0; i < 6; i++) {

int x = gearX[i];

int y = gearY[i];

if (i == highlight) {

display.fillRect(x - 2, y - 2, 20, 18, SSD1306_WHITE);

display.setTextColor(SSD1306_BLACK);

} else {

display.setTextColor(SSD1306_WHITE);

}

display.setTextSize(2);

display.setCursor(x, y);

display.print(gearLabels[i]);

}

// Optional: Show Neutral if no gear is selected

if (highlight == -1) {

display.setTextSize(2);

display.setTextColor(SSD1306_WHITE);

display.setCursor(40, 48);

display.print("N");

}

display.display();

}🧰 Notes

- You can change the line coordinates if your OLED is a different resolution.

- Works best with 128×64 OLEDs (SSD1306).

- All six gears are laid out in an accurate H-pattern.

- The highlighted gear gets inverted colors for visibility.

- If no switch is pressed, “N” (Neutral) is shown.

✅ Conclusion: Manual Transmission Gear Indicator with H-Pattern

You’ve now built a functional and visually enhanced gear position indicator for a manual transmission car using:

- Arduino Nano for logic and input reading

- Limit switches for real-time gear detection

- 0.96″ OLED display to show a classic H-pattern with highlighted gear feedback

This setup provides a clear, intuitive way to monitor gear selection on both physical and graphical interfaces. It’s especially useful for simulators, DIY dashboard projects, or driver training rigs.

🛠️ Suggested Improvements and Tips

1. Debounce Switch Inputs

Avoid gear flickering or false reads:

delay(20); // small debounce delay

Or implement proper software debouncing using millis().

2. Neutral Detection Enhancements

Currently, Neutral is when no gear is pressed. To improve:

- Add a dedicated “Neutral” switch

- Or detect the state where the stick is between gates

3. Add Sound or Haptic Feedback

- A small piezo buzzer for gear change tones

- Or vibrational feedback if you want tactile confirmation

4. Animated Transitions

Use frame-based drawing for smoother gear change animation:

- Slide highlight boxes

- Fade effects when switching gears

5. Backlit or Themed Displays

- Use color OLED (if available) for vibrant themes

- Customize gear highlight color (e.g., red for R, blue for normal gears)

6. Serial Output or Logging

- Send gear changes via

Serial.print()for debugging or telemetry logging - Integrate with an app or data logger

7. Upgrade Display for Advanced UI

- Use a TFT display (e.g., 1.8″ or 2.4″ SPI TFT) for full-color, richer graphics

- Integrate touchscreen to simulate automatic/manual mode switching

8. Encapsulate in a Dashboard Housing

Build a physical enclosure for the screen and gear detector:

- Use 3D printed or laser-cut dashboard panel

- Mount switches firmly under the shifter gate